The EndoPilot Endo Motor System has been designed to ensure ultimate control and safety in the mechanical preparation of the root canal space. The many unique features of the EndoPilot Endo Motor System are explained below.

endo specific

The EndoPilot Endo Motor is specifically designed for endodontic use. Running from 200 to 1,000rpm the motor operates with a 1:1 ratio contra angle for enhanced efficiencies and precise torque control. There are no unnecessary gears and there is absolutely no need for high speed reduction typical with many ‘endo’ motors. This is the smoothest running motor on the market and offers unprecedented safety parameters.

ergonomic

The EndoPilot handpiece has been designed to eleviate user fatigue and provide an enhanced level of control. Due to the fact that there are no reduction gears in the contra angle the weight is more appropriately distributed - there is not the 'top heavy' feeling that many handpieces suffer from. The handpiece rests comfortably between the thumb and forefinger.

bi-force technology (B-FT)

The EndoPilot Bi-Force Technology minimizes the binding of files in canals by means of alternating left-right rotations (twist function) once 80% of the maximum torque value is reached. Uniquely the EndoPilot motor controls the maximum applied torque in both clockwise and counter clockwise directions. This eliminates the potential for over torque forces being applied to the file as the handpiece works to loosen a file that may become bound in the canal.

led notifications

The EndoPilot handpiece features a circular set of coloured LED lights at the base of the motor. These lights act as a visual aid and provide instant feedback on rotation, torque limits and working length location to the user. For example, in terms of torque limit a solid green light indicates that the applied torque is below 80% of the maximum value set for that file and a solid red light means that the torque is above 80% of the maximum value.

approaching apex torque reduction (aatr)

The EndoPilot features a patented function where the cutting output of a file is limited in the apical area to ensure continuous evacuation of dentinal debris and reduce the risk of over instrumentation. Additionally, the EndoPilot does not use auto-reverse technology, minimizing the risk of depositing dentinal debris into the apical area.

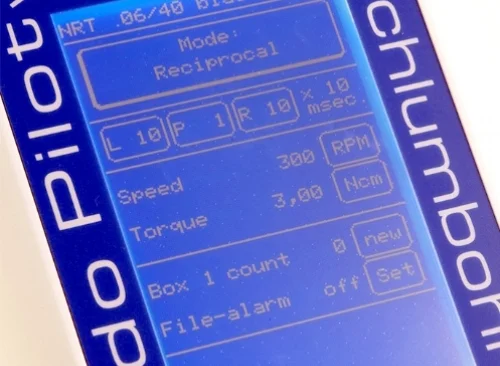

reciprocation

The EndoPilot is fully capable of operating in a reciprocating (back and forth) mode with NiTi files. Uniquely, the EndoPilot allows you to adjust the left motion, the right motion and the length of the pause in milliseconds for absolute accuracy. This complete control of the file action makes it possible to have highly customized file sequences.